The National Hemp Growers Collective and Troy University aim to use hemp fiber to create biodegradable plastics.

Earlier this month, the National Hemp Growers Collective entered into a partnership with the Center for Materials and Manufacturing Sciences at Troy University in Alabama to develop a process for using hemp fiber to create biodegradable plastics, according to a recent report.

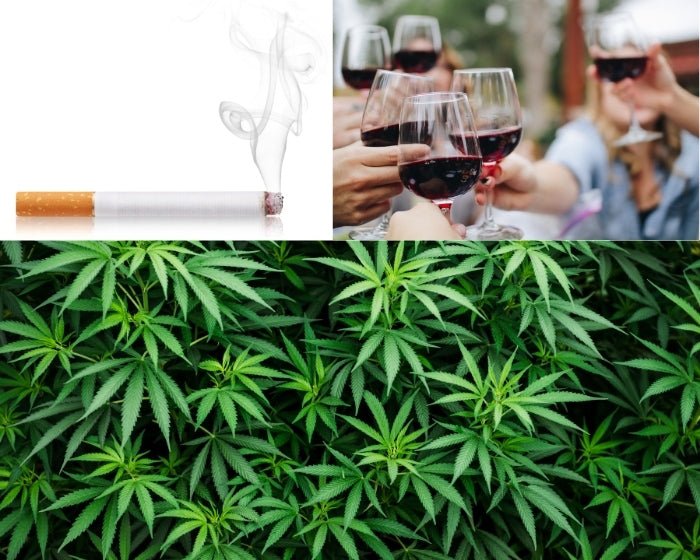

With the passage of the 2018 Farm Bill, which legalized the production of hemp in the United States again, there has been increased interest in the myriad of ways hemp can be used to address climate change. Hemp plastic is one of those potential new products seen as a possible alternative solution for manufacturing a more eco-friendly version of plastic.

As Dr. Jack Hawkins Jr. of Troy University states, “Not only is it good for the economy, but (it is) also good for our world.”

"Not only is it good for the economy, but (it is) also good for our world.”

- Dr. Jack Hawkins, Jr., Troy University

Hemp plastic is a "bioplastic" made from the cellulose of hemp plants, which, unlike plastics manufactured with petroleum products, is a biodegradable material. In addition, hemp-based plastics can be created using the byproducts leftover from hemp grown for producing CBD and CBG, including leaves, seed husks, and stems, which means farmers could gain a new potential revenue stream for their hemp crops.

Turning hemp into plastic can vary, as there are many separate ways to transform hemp into hemp plastic. The primary step in the progression involves extracting cellulose from the hemp plant, which is accomplished by pulping hemp plants and separating the cellulose using water, acid solutions, and heat and pressure.

The resulting cellulose can then be made into several different types of hemp bioplastic, including (High-Grade Hempseed):

- Hemp cellulose: An organic polymer primarily used to make paper but can also be utilized to create a wide range of other plastics.

- Cellophane and Rayon: Designated as regenerated cellulose fibers, these fibers are used to make cellophane film (material used to seal containers) or rayon fiber (sheets, curtains, clothing)

- Cellulose Nanocrystals: These are used in different applications, including nanopaper, barrier films, and more.

- Nanocellulose: A “pseudoplastic” that can alternate between a gel-like substance or a liquid. Nanocellulose has multiple valuable uses, including as a highly absorbent agent used to help clean up oil spills and make sanitary products.

- Composite Hemp Plastics: These are plastics that incorporate cellulose as well as a range of other polymers that may be natural or synthetic (building materials, boats, car panels and more).

To truly appreciate the impact of this partnership and the resulting impact hemp plastic can have regarding climate change, we must first understand the devastating effects plastic currently has on our environment.

According to Science Advances, over 8.3 billion metric tons of plastic have been created in the past six decades. And the vast majority of that plastic is made from petroleum.

Extracting petroleum from the ground and transforming it into plastic is not a clean process. The EPA estimates that producing one ounce of polyethylene (PET), the most common type of plastic, also generates one ounce of carbon dioxide.

However, the most devastating aspect of plastic made from petroleum is that it lasts for a very long time. In the case of plastic bags, plastic can stick around for as little as 20 years. But for other products, such as disposable diapers and toothbrushes, it can persist for an unimaginable 500 years. And the vast majority of plastic (roughly 79%) ends up in landfills or the environment. Hemp plastic offers a much better and cleaner alternative.

The advantages of hemp plastic, as alluded to earlier, are numerous and include (from High-Grade Hempseed):

- Biodegradable - Hemp plastic decomposes in three to six months.

- Renewable Resource - Unlike petroleum, hemp is a renewable resource. It grows quickly and easily and matures in roughly four months. It can also grow in a wide variety of soils.

- Hemp Makes a More Durable Plastic - Hemp plastic is more robust, durable, and lighter than petroleum-based plastic.

- No Toxins - Hemp plastic contains no dangerous toxins, unlike petroleum-based plastic.

- Easy to Recycle - Despite high-profile recycling campaigns for petroleum-based plastic, recycling is challenging. Conversely, hemp plastic is easy to recycle.

- Carbon Trapping - Similar to “hempcrete” in construction, when hemp plastic is made, carbon is locked into the plastic, helping to sequester excess carbon from being released into the atmosphere.

Dr. Hawkins concludes, “When you think about the advantage of hemp-based bioplastic, it makes for a better environment. It’s biodegradable, it’s a renewable resource, and it’s tough. This is a significant step in an initiative that will grow this University in an exciting new way.

We look forward to what the National Hemp Growers Cooperative can mean to this partnership.”

"When you think about the advantage of hemp-based bioplastic, it makes for a better environment. It’s biodegradable, it’s a renewable resource, and it’s tough. This is a significant step in an initiative that will grow this University in an exciting new way. We look forward to what the National Hemp Growers Cooperative can mean to this partnership.”

- Dr. Jack Hawkins, Jr., Troy University

Now that hemp is gaining momentum as a viable crop (CBD and CBG) for farmers, both in the U.S. and abroad, to invest their land and resources, the opportunity to utilize hemp as a worthwhile and climate-saving alternative to petroleum-based plastics seems increasingly promising. And with groundbreaking initiatives like the partnership between the NHGC and Troy University taking shape, a future without choked landfills and ever-rising global temperatures is a true potential reality.