Each person in the United States uses about 680 pounds of paper each year, according to data from the University of Southern Indiana. The average American uses about seven trees worth of paper and wood products every year, which amounts to a collective American demand for roughly 2 billion trees worth of products. About 1 billion trees worth of these products are reportedly thrown away each year in the U.S.

Although trees are a renewable resource, they may not be the best resource to meet this staggering demand. Harvesting this number of trees each year can reportedly lead to habitat loss, species extinction, and climate change. Fortunately, we have other options.

Hemp plants can grow much faster than trees, and they can also be processed into a wide variety of different paper products. According to the Ministry of Hemp, one acre of hemp can produce the same amount of paper as four to 10 acres of trees over a 20 year period. Additionally, hemp plants can be harvested after four months, whereas trees reportedly take 20 to 80 years.

Both the outer fibers and inner core of the hemp stalk can be turned into paper. Paper made from the fibrous outer layer of the stalk is “thin, tough, brittle, and rough,” according to the Ministry of Hemp.

Paper made from the pulp at the center of the stalk, which is also called the hurd, is not as strong as the paper made from the outer fibers, but this paper is easier to make. It is also reportedly “softer, thicker, and preferable for most everyday purposes.”

Hemp hurds are chemically similar to wood, which means that it can be a good candidate to replace paper products made from trees.

Hemp also has a high concentration of cellulose, which is the main component in paper, and a low amount of lignin, which must be removed before the pulp can be used in paper. Hemp can reportedly have up to 85% cellulose and between 5 % and 24% lignin. Wood has only 30% cellulose and 20% to 35% lignin.

Many of the paper products made with hemp are even higher quality than their wood-based counterparts. Hemp paper is reportedly more durable than paper made from trees and does not yellow, crack, or deteriorate the way tree paper does.

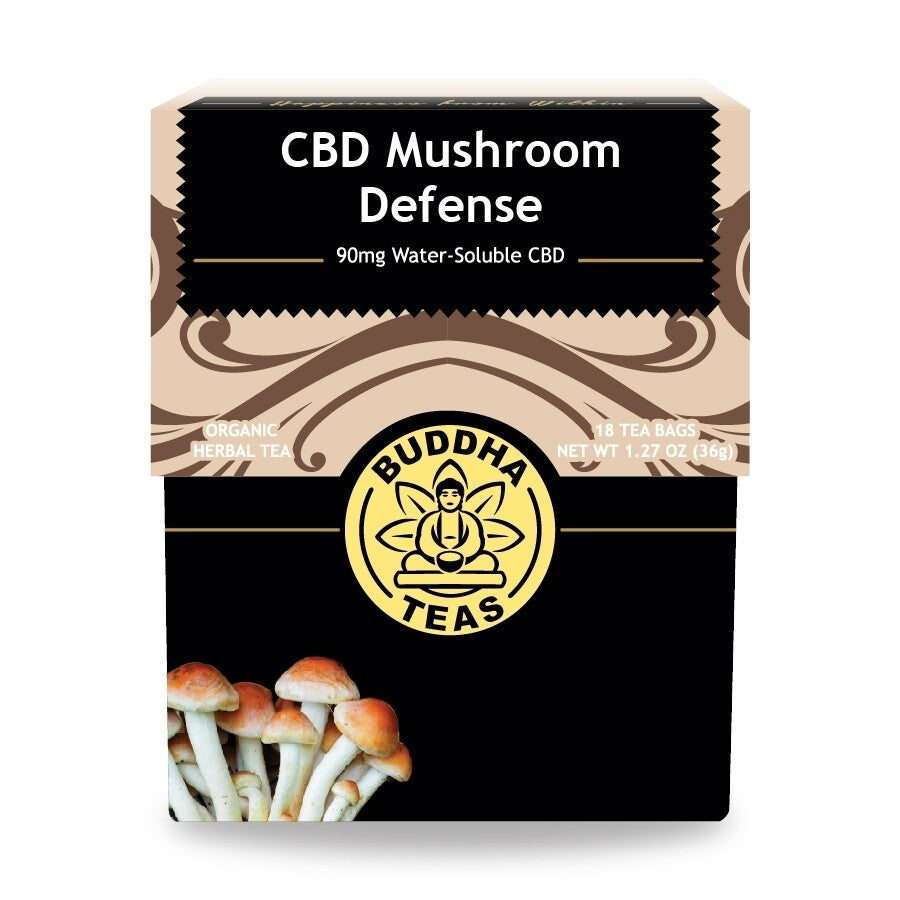

Unfortunately, most of the paper products we see in stores today is still made with trees. The ministry of Hemp claims that one reason for this is that the U.S. has not yet built up a large supply of hemp. Although farmers reportedly grew over 75,000 acres of hemp in 2018, most of it was used to create CBD oil or body care products. However, this is expected to change.

Data Bridge Market Research reportedly predicts the global hemp paper market to grow at a rate of 36.8% between 2020 and 2027.

The report from this market research company points out that hemp can be used for a wide variety of products, such as cigarette paper, filter paper, tea pouches, stationary, Bible paper and others. It adds that the projected growth is partially due to the “[e]volving applicability of hemp products”. This means that as companies develop more ways to use hemp paper, the demand for hemp paper products will increase.

Switching from tree paper to hemp paper can make a big environmental impact. However, the infrastructure is still being established in the U.S., and the products are still being perfected. While there are some companies that manufacture hemp paper products, consumers may not be able to replace all their tree paper products with hemp ones — at least not yet.

Sources

[2] https://ministryofhemp.com/blog/hemp-paper/#deforestation

[3] https://www.databridgemarketresearch.com/reports/global-hemp-paper-market?SR